Predictive Maintenance

How it works:

AI models on devices analyze sensor data (vibration, temperature, etc.) from machines to detect early signs of wear or failure.Benefits:

Reduces unplanned downtime, extends equipment life

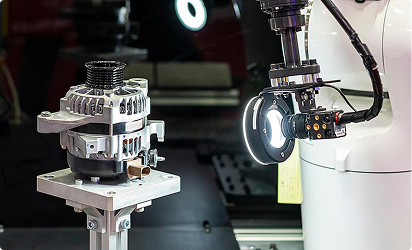

Visual Inspection

How it works:

Cameras combined with AI on device inspect products for defects in real time.Benefits:

Increases product quality, reduces scrap rates

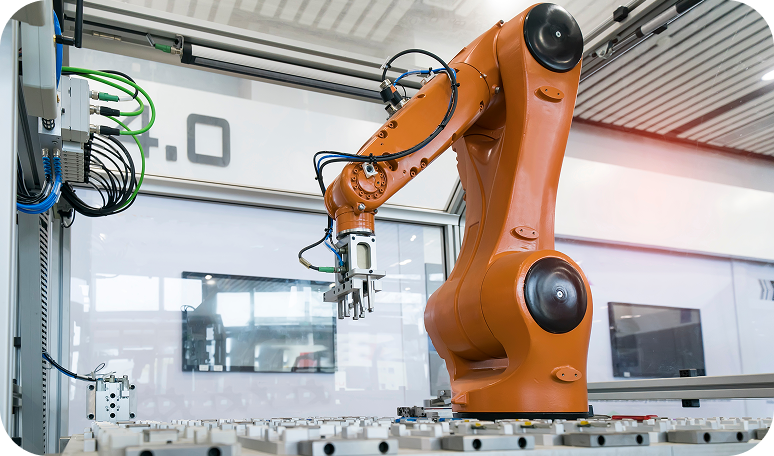

Robotics/Cobots

How it works:

Physical AI powers real-time decision-making in robots, allowing them to adapt to changing environments and interact safely with humans.Benefits:

Increases efficiency, enhances flexibility, improves safety

Inventory Monitoring

How it works:

AI-enabled sensors and cameras track materials and parts, providing instant feedback on inventory levels.Benefits:

Minimizes shortages or overstocking

Anomaly Detection

How it works:

Physical AI models continuously monitor sensor data (e.g., pressure, current, temperature, acoustic signals) to detect patterns that deviate from normal operating conditions.Benefits:

Identifies faults, deviations in real-time, for immediate response

Measurement Analysis

How it works:

Physical AI processes data from vision systems, laser scanners, or coordinate measuring machines (CMMs) to assess part dimensions and tolerances during production.Benefits:

100% in-line inspection and auto correction without slowing production.

Assembly

Assembly Procedure

Overview

Equipment Operation Procedure

Overview

Safety & Training Procedure

Overview

Product Assembly Verification

Overview

Industrial Manufacturing

Precision manufacturing solutions

SiMa.ai Solution Detail

Products

- Hardware: MLSoC and MLSoC Modalix

- Software: Palette and Palette Edgematic

Services

- Enable customer pipeline on SiMa.ai chip

- Integrate across multiple product lines and factories

- MLOPs

Solution Overview

- Multimodal compute

- Industry leading frames-per-second performance

- Compute at the edge, enabling low latency, critical accuracy

Challenges

- Latency

- Throughput

- Varying video processing streams

Solution

- MLSoC – Multimodal compute at the edge

- Palette SDK & Edgematic – Deploy any model

Solution

- 10X improvement over incumbent solution

- Early defect detection

- Ease of integration in production

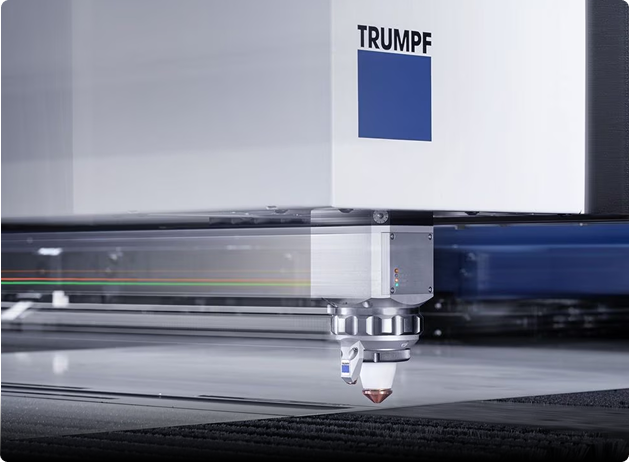

“AI has high strategic relevance for TRUMPF. Our expertise in laser processes and manufacturing helps us to develop smart software for production purposes. SiMa.ai is the ideal partner for this next big step towards intelligent industrial solutions”

Richard Bannmüller

CTO, TRUMPF Laser Technology